30 Dec

Unlocking Efficiency in Construction: The Critical Role of Gypsum Retarders and YuanlianChemical's Innovative Solutions

Gypsum-based materials are fundamental to modern construction, manufacturing, and art. However, their rapid setting time – often just minutes – presents significant challenges for complex applications. This is where gypsum retarders become indispensable chemical additives. By precisely controlling the hydration reaction between gypsum (calcium sulfate hemihydrate) and water, these specialized compounds extend the workable life of gypsum slurries, enabling higher quality outcomes, reduced waste, and enhanced design flexibility across diverse industries.

Core Function and Mechanism:

Gypsum retarders work by adsorbing onto the surface of gypsum crystals during the initial dissolution phase. This adsorption layer acts as a barrier, inhibiting the nucleation and growth of dihydrate crystals – the process responsible for setting and hardening. The effectiveness hinges on the retarder's chemical composition and dosage, allowing for precise control over setting time, from modest extensions for intricate casting to substantial delays for large-scale pumping operations. Key performance indicators include consistent retardation without compromising final strength, minimal impact on water demand, and predictable behavior under varying temperature and mix conditions.

Pivotal Applications Across Sectors:

1. Building Plasters & Drywall Joint Compounds: In plastering walls and ceilings, and finishing drywall seams, extended workability is non-negotiable. Retarders allow applicators sufficient time for proper spreading, leveling, and achieving smooth, seamless finishes over large areas, significantly improving productivity and aesthetic quality. Premature setting leads to poor adhesion, surface defects, and costly rework.

2. Precast Gypsum Products & Molds: Manufacturing intricate decorative elements, ceiling tiles, or lightweight blocks requires gypsum slurry to flow freely into complex molds. Retarders ensure complete mold filling and capture of fine details before hardening begins, resulting in precise, high-definition products with excellent surface reproduction and minimal air voids.

3. Self-Leveling Underlayments (SLU): Achieving perfectly flat and smooth floors demands gypsum-based SLUs to remain fluid long enough to flow and self-level. Retarders are critical here, providing the extended flow time necessary for the material to spread evenly and eliminate undulations before the rapid setting phase commences, ensuring a flawless substrate for final flooring.

4. Medical & Dental Applications: Precision is paramount in creating orthopedic casts and dental models. Retarders give medical professionals and technicians ample time to position limbs accurately or pour intricate dental impressions without rushing, ensuring patient comfort and the creation of accurate, detailed molds for prosthetics or study models.

5. Artistic Casting & Pottery: Sculptors and ceramicists rely on gypsum for mold making. Retarders allow them to meticulously pour plaster around delicate originals or into complex shapes, capturing every nuance without the stress of immediate setting. This facilitates the creation of high-fidelity reproductions and intricate artistic works.

6. Large-Scale Construction & Pumping: For projects requiring vast quantities of gypsum plaster or mortar pumped over long distances or to significant heights, extended set times are essential. Retarders prevent setting within the delivery system, ensuring continuous, efficient placement and eliminating the risk of blockages and equipment damage.

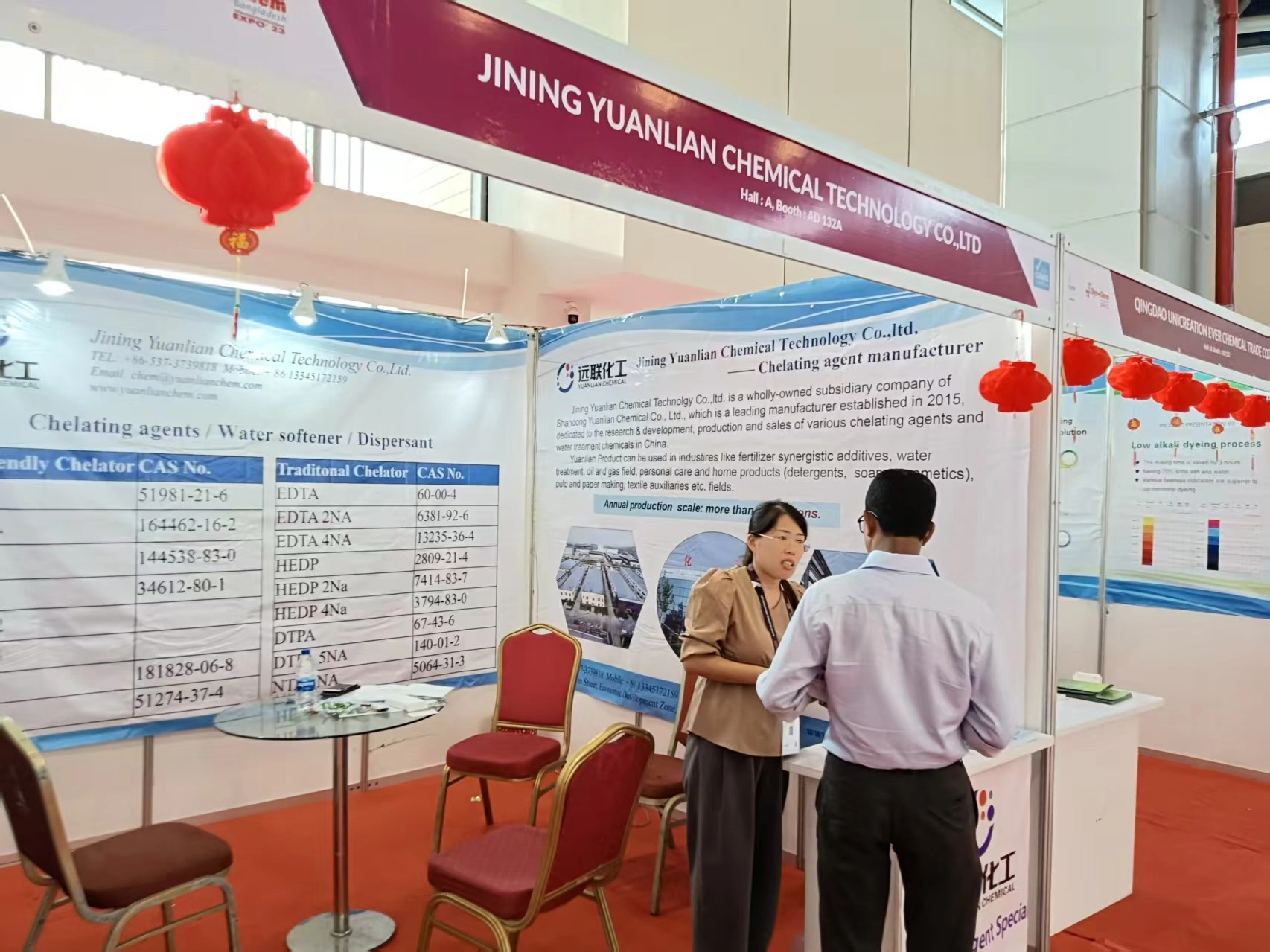

YuanlianChemical: Delivering Advanced Retarder Technology

Recognizing the critical need for high-performance and reliable gypsum retarders, YuanlianChemical has invested significantly in research and development. Their product line, exemplified by solutions like WN-721, is engineered to meet the exacting demands of modern industry:

* Precision Control: Offering predictable and linear retardation response to dosage, allowing fine-tuning for specific project requirements.

* Strength Preservation: Formulated to minimize any negative impact on the ultimate compressive and flexural strength of the cured gypsum product.

* Consistency & Reliability: Rigorous quality control ensures batch-to-batch uniformity, critical for large-scale production and consistent application results.

* Optimized Performance: Low dosage requirements for effective retardation, improving cost-efficiency and minimizing potential side effects on other properties like water demand or adhesion.

* Technical Expertise: YuanlianChemical provides comprehensive technical support, assisting customers in selecting the optimal retarder and dosage for their specific gypsum type, application method, and environmental conditions.

Beyond Simple Delay: The Broader Value Proposition

The strategic use of advanced gypsum retarders delivers tangible benefits beyond just extended workability:

* Enhanced Productivity: Reduced urgency allows workers to focus on quality application, covering larger areas per batch and minimizing rework due to premature setting.

* Superior Finishes: Ample time for detailed finishing work leads to smoother surfaces and better aesthetics in plasters, casts, and precast items.

* Reduced Material Waste: Avoiding setting before placement or during pumping significantly cuts down on discarded batches.

* Design Freedom: Enables the creation of complex geometries and large-scale structures that would be impossible with unretarded gypsum.

* Process Efficiency: Facilitates automation and mechanized application (like pumping and spraying) by providing a manageable time window.

Conclusion:

Gypsum retarders are far more than simple additives; they are sophisticated chemical tools that unlock the full potential of gypsum-based materials. By granting precise control over setting time, they empower industries to achieve higher quality, efficiency, and innovation. YuanlianChemical, through its commitment to advanced formulations like YL-GR200 and dedicated technical support, positions itself as a vital partner for manufacturers, contractors, and artisans seeking reliable, high-performance solutions to master the challenges of gypsum application. Choosing the right retarder technology is a strategic decision directly impacting the success, cost-effectiveness, and quality of gypsum-dependent projects worldwide.