Product Characteristics: Non-toxic, Non-irritating, Non-flammable, Non-explosive

Gypsum Setting Time Curve

WN-701

is a new type of alkali-resistant amino acid-based gypsum retarder,

specifically designed for industrial desulfurized gypsum and

phosphogypsum. At an extremely low dosage, this product delivers

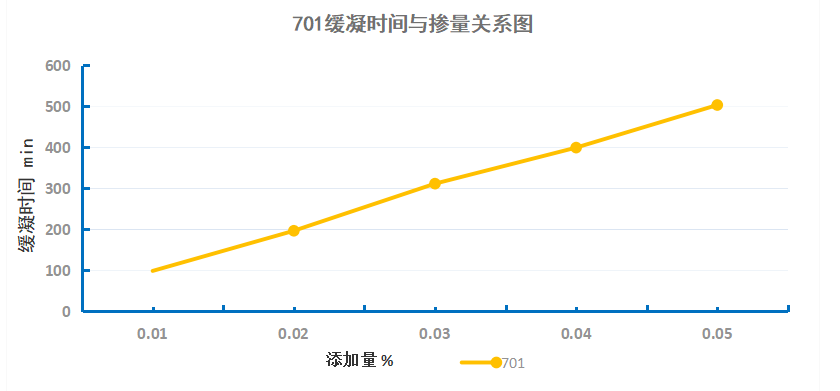

excellent retarding effects with a clear and controllable linear

relationship between dosage and retarding time—allowing customers to

precisely adjust the setting time as needed. Meanwhile, it has minimal

impact on the long-term strength of gypsum products.

- Industrial desulfurized gypsum

- Phosphogypsum

- Other industrial by-product gypsum

✅ High-Efficiency Retardation at Low Dosage

An ideal retarding effect can be achieved with a dosage of only 0.03-0.04%.

✅ Linear Controllability

The retarding time and dosage show a clear linear relationship, enabling precise adjustment.

✅ Strong Adaptability

Excellent compatibility with various types of gypsum.

✅ Minimal Impact on Strength

Has very little effect on the long-term strength of gypsum products.

✅ Good Compatibility

Well-compatible with gypsum additives such as water reducers, defoamers, and stabilizers.

✅ Uniform Dispersion

Ensures uniform and stable mixing with excellent dispersibility.

✅ Stable Quality

Reliable and stable production process ensures high consistency in product quality.

Recommended Dosage: 0.03-0.04% (based on the weight of gypsum).

Notes:

- Differences in mineral composition and calcination quality of gypsum

resources across regions may affect the setting time of gypsum.

- A trial mixing test should be conducted when using the product for the first time to determine the optimal dosage.

- The dosage can be adjusted according to actual needs to control the setting time.

This product exhibits good compatibility with common gypsum additives, including water reducers, defoamers, and stabilizers.

- Packaging Specification: 25 kg/double-layer moisture-proof packaging (customized packaging available).

- Storage Conditions: Store in a cool, dry place; protect from moisture and high temperatures.

- Special Requirements: The product has slight hygroscopicity and must be sealed to prevent caking.

- Shelf Life: 12 months from the date of production.

- Handling After Expiration: If the product exceeds its shelf life, it must be tested and verified before use.

This

product is non-toxic and non-irritating, requiring no special

protective measures during operation. In case of accidental inhalation,

move to a well-ventilated area immediately.

[Safety Data Sheet (SDS)] | [Technical Data Sheet (TDS)] | [Application Case Manual]

Please contact us to obtain free samples and professional technical guidance.

Due

to variations in gypsum raw materials, it is recommended to conduct a

trial mixing test to determine the optimal dosage when using the product

for the first time.